close

Choose Your Site

Global

Social Media

Views: 3245 Author: Site Editor Publish Time: 2025-09-26 Origin: Site

Nonionic surfactants refer to surfactants that do not ionize in aqueous solution. Their hydrophilic groups are mainly composed of oxygen-containing groups (typically ether and hydroxyl groups). The lipophilic part of the molecule is derived from higher fatty alcohols, alkylphenols, fatty acids, fatty amines, and oils, while the water solubility comes from the polyoxyethylene ether groups and terminal hydroxyl groups within the molecule.

Because nonionic surfactants do not ionize in water, they exhibit several advantages over ionic surfactants. For instance, they have good solubility in both water and organic solvents, show high stability in solution, and are less affected by strong electrolytes, inorganic salts, acids, and bases. They are also highly compatible with other types of surfactants, making them well-suited for blending and formulation.

Most nonionic surfactants exist in liquid or paste form, and their solubility in water decreases with increasing temperature. They possess a wide range of functional properties, including excellent detergency, dispersion, emulsification, foaming, wetting, solubilization, antistatic performance, leveling, corrosion inhibition, sterilization, and protective colloid effects. As a result, they are widely used in textiles, papermaking, food, plastics, leather, fur, glass, petroleum, chemical fibers, pharmaceuticals, pesticides, coatings, dyes, fertilizers, films, photography, metalworking, mineral processing, building materials, environmental protection, cosmetics, firefighting, agriculture, and many other fields.

These are polyether compounds obtained by condensing ethylene oxide with long-chain fatty alcohols, alkylphenols, or higher fatty acid polyol esters.

Representative Raw Materials:

Fatty alcohol polyoxyethylene ethers

Alkylphenol polyoxyethylene ethers

Polyol fatty acid ester polyoxyethylene ethers

Fatty acid methyl ester ethoxylates

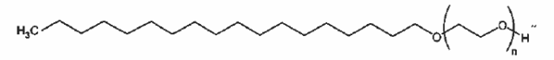

Fatty alcohol polyoxyethylene ethers (AEO), also known as polyoxyethylene fatty alcohol ethers, are the fastest-growing and most widely used type of nonionic surfactants. This class of surfactants is formed by the condensation of polyethylene glycol (PEG) with fatty alcohols, and can be represented by the general formula:

RO(CH₂CH₂O)ₙH

where n is the degree of polymerization. Different varieties exist depending on the degree of polymerization of PEG and the type of fatty alcohol used.

Commercially, these are sold under trade names such as Brij. For example, Brij 30 and other Brij products are obtained by condensing varying numbers of ethylene oxide units with lauryl alcohol, and they are commonly used as O/W type emulsifiers.

Example:

Ceteareth-10 (INCI name)

Alias: AEO-10

Chemical name: Cetearyl alcohol polyoxyethylene ether-10

Appearance: White waxy solid

Solubility: Insoluble in water

HLB value: 12.9

Structural formula: n = 10

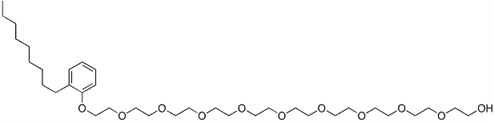

Also known as TX or OP, alkylphenol polyoxyethylene ether-n shows good water solubility when n is greater than 8. Alkylphenol polyoxyethylene ethers (APEOs) are an important class of polyoxyethylene nonionic surfactants. They are characterized by stable properties, resistance to acids and alkalis, and relatively low cost.

APEOs are widely used in the production of high-performance detergents and have long been one of the most commonly used raw materials for textile auxiliaries. They are frequently added to detergents, scouring agents, spinning oils, softening agents, wool processing oils, and metal cleaning agents.

Example:

Nonoxynol-10 (INCI name)

Aliases: TX-10, Nonylphenol polyoxyethylene (10) ether

Appearance: Transparent liquid

Properties: Excellent wetting, emulsifying, dispersing, solubilizing, foaming, defoaming, and detergency functions

HLB value: 13.3

Structural formula:

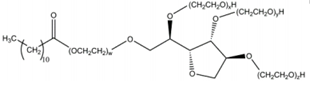

A typical representative of this category is polyoxyethylene sorbitan esters (Tween), also known as polysorbates. They are condensation products of sorbitan (Span) and ethylene oxide. Due to the presence of multiple hydrophilic polyoxyethylene groups in the molecule, these surfactants exhibit strong hydrophilicity. Common types include T-20, T-21, T-40, T-60, T-61, T-65, T-80, T-81, and T-85.

Example:

Polysorbate 20 (INCI name)

Aliases: T-20, Tween 20, Polyoxyethylene (20) sorbitan monolaurate

Appearance: Light yellow to yellow viscous liquid at room temperature

Odor: Slight characteristic odor

Solubility: Soluble in water, ethanol, methanol, and ethyl acetate; insoluble in mineral oil and petroleum ether

Functions: Emulsifier, dispersant, solubilizer

Structural formula:

Fatty acid methyl ester ethoxylates (FMEE) are produced by the addition reaction of fatty acid methyl esters with ethylene oxide under catalytic conditions. Compared with fatty acid polyoxyethylene ethers, the ester group in FMEE is more stable, particularly showing significantly improved resistance to acids and alkalis.

The raw material, fatty acid methyl ester, is itself a type of defoaming agent. After ethoxylation, FMEE retains the low-foaming characteristics while offering enhanced performance. FMEE is mainly used as a high-efficiency detergent, featuring:

Low foaming

High cloud point

Excellent cleaning ability

Outstanding dispersing properties

Its strong dispersibility is especially important in industrial applications. With the ongoing trend toward smaller bath ratios in processing operations, FMEE effectively prevents dirt in the working solution from agglomerating into clumps, and avoids re-deposition onto equipment or processed materials.

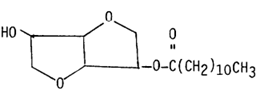

Structural formula:

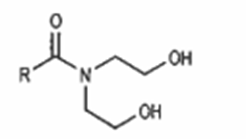

The main components can be represented as RCON(CH₂CH₂OH)₂. They are stable in both acidic and alkaline conditions, with strong wetting and emulsifying properties. When incorporated into soaps, they can enhance foaming ability, detergency, and resistance to hard water. Alkanolamides are produced by the condensation of fatty acids with monoethanolamine (MEA) or diethanolamine (DEA). Their hydrophilic groups are the amide and hydroxyl groups, while the hydrophobic group is the long-chain alkyl. As a type of nonionic surfactant, they can function as detergents, wetting agents, and emulsifiers.

In cosmetics, their main uses include acting as thickening agents and foam stabilizers.

Example:

Cocamide DEA (INCI name)

Aliases: Coconut fatty acid diethanolamide, 6501, Cocamide diethanolamine

Appearance: Colorless viscous liquid

Solubility: Soluble in water

Properties: Excellent foaming, foam stabilization, and antistatic effects

According to the Cosmetic Safety Technical Specification (2015 Edition) in China, Cocamide DEA is a restricted substance with specific quality requirements:

It must not be used together with nitrosating systems, to avoid nitrosamine formation.

Maximum secondary amine content in products: 0.5%

Maximum nitrosamine content in products: 50 µg/kg

Maximum secondary amine content in the raw material: 5%

Must be stored in containers free of nitrites.

Structural formula:(1:1 type alkylamide DEA, where R is lauric acid)

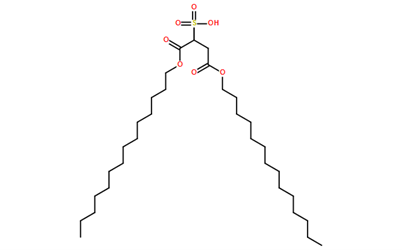

Polyol fatty acid esters are obtained by the esterification of polyols with fatty acids. The hydrophobic part comes from the long carbon chain of the fatty acid, while the hydrophilic part comes from the unesterified hydroxyl groups. This category includes glycerol fatty acid esters and sorbitan esters.

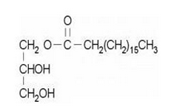

Glycerol fatty acid esters are formed by the reaction of glycerol with fatty acids. The types that act as surfactants are mainly monoesters and diesters, which are primarily used as emulsifiers. Generally, a mixture of monoesters and diesters can be used, but products with about 90% monoester content can also be obtained through distillation and refining.

The fatty acids used include stearic acid, palmitic acid, myristic acid, oleic acid, and linoleic acid. In most cases, mixed fatty acids with stearic acid as the main component are employed.

Example:

Glyceryl Stearate (INCI name)

Aliases: Glyceryl monostearate, Glyceryl stearic acid ester

Appearance: White flakes

Solubility: Insoluble in water

Functions: Used mainly as an emulsifier, co-emulsifier, and emollient

Structural formula:

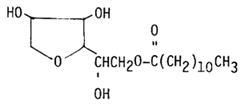

Also known as Span, sorbitan fatty acid esters, or anhydrosorbitol fatty acid esters, these compounds are produced by the esterification of sorbitan (dehydrated sorbitol) with various fatty acids. The Span series exhibits very low solubility in water and is therefore classified as lipophilic surfactants.

In formulations, they are often used in combination with Tween (polysorbate) surfactants. The Span series includes S-20, S-40, S-60, S-65, S-80, and S-85. They are available in a wide range of commercial grades, with well-established manufacturing processes. These materials demonstrate emulsifying properties and compatibility with other types of surfactants.

Spans are widely applied in the food, pharmaceutical, cosmetic, and textile industries, mainly as oil-soluble, liquid or waxy compounds. They are particularly suitable as water-in-oil (W/O) emulsifiers.

Example:

Sorbitan Laurate (INCI name)

Aliases: S-20, Span 20, Sorbitan monolaurate, Anhydrosorbitol monolaurate

Functions: W/O emulsifier, stabilizer, dispersant

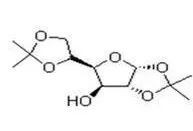

Structural formula:

I、

II、

III、

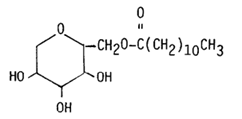

Sucrose esters refer to sucrose fatty acid esters. Sucrose (C₁₂H₂₂O₁₁) is a condensation product of one glucose molecule and one fructose molecule. Since sucrose contains multiple free hydroxyl groups, it has good water solubility and can undergo esterification with higher fatty acids.

Sucrose esters are easily biodegradable, absorbable by the human body, non-toxic, and non-irritating to the skin. Because of these properties, they are widely used as emulsifiers and additives in foods and cosmetics. They can also serve as ingredients in low-foaming detergents.

Structural formula:

Alkylamine oxides are readily soluble in water and polar organic solvents. They are classified as weak cationic amphoteric surfactants: in aqueous solution they behave as cationic under acidic conditions, and as nonionic under alkaline conditions.

They possess excellent thickening, antistatic, softening, foaming, foam-stabilizing, and detergency properties. In addition, they exhibit bactericidal activity, calcium soap dispersing ability, and good biodegradability, making them environmentally friendly surfactants widely used in household and personal care products.

In cosmetic formulations, alkylamine oxides can also serve as thickening agents and foam stabilizers.

Example:

Lauramine Oxide (INCI name)

Aliases: Dodecyldimethylamine oxide, OB-2 conditioner, OA-12

Appearance: Colorless to pale yellow transparent liquid

Solubility: Soluble in water

N-Alkylpyrrolidones exhibit properties similar to alkylamine oxides. Structurally, they are classified as nonionic surfactants, but in acidic media the molecule undergoes protonation, generating a cationic group and thus showing weak cationic behavior.

They are used in hair care products as thickening agents, foam stabilizers, and conditioning agents, and can also function as solubilizers for fragrances and other components.

Example:

Lauryl Pyrrolidone (INCI name)

Aliases: N-Laurylpyrrolidone

NEWSLETTER SIGN UP